Sign up to get the latest product announcement and offer.

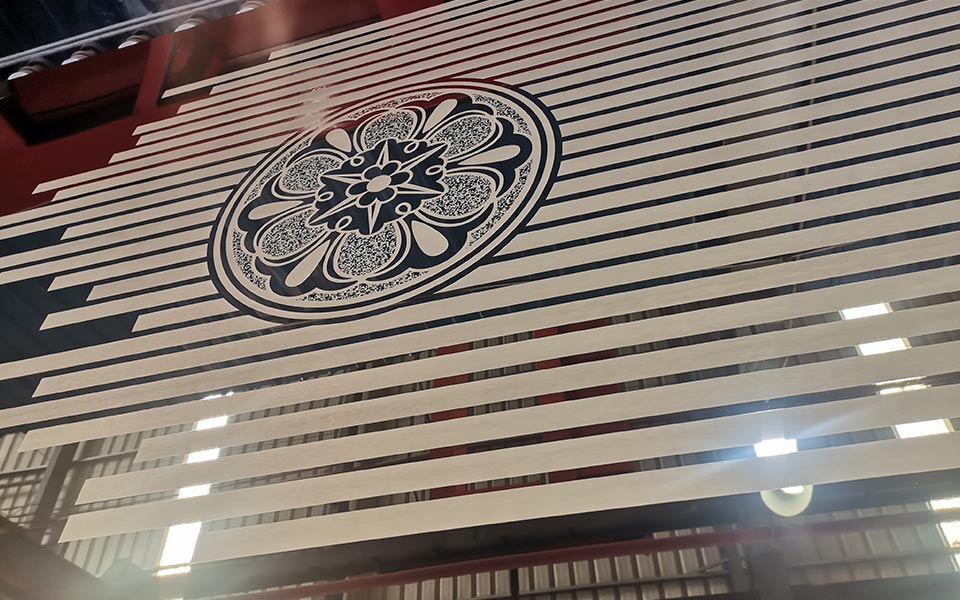

Etching stainless steel sheet have match mold for elevator door and elevator cabin.It use 304 1.0mm stainless steel sheet material,and PVD gold color on Etching pattern.

Grade: :

201/304/316Surface: :

Etching FinishSize: :

1219*2438mm,1219*3048mm or customizedColor :

SilverLead Time: :

7-25 days after depositMOQ :

50pcsDeep Etching Stainless Steel for Elevator Door

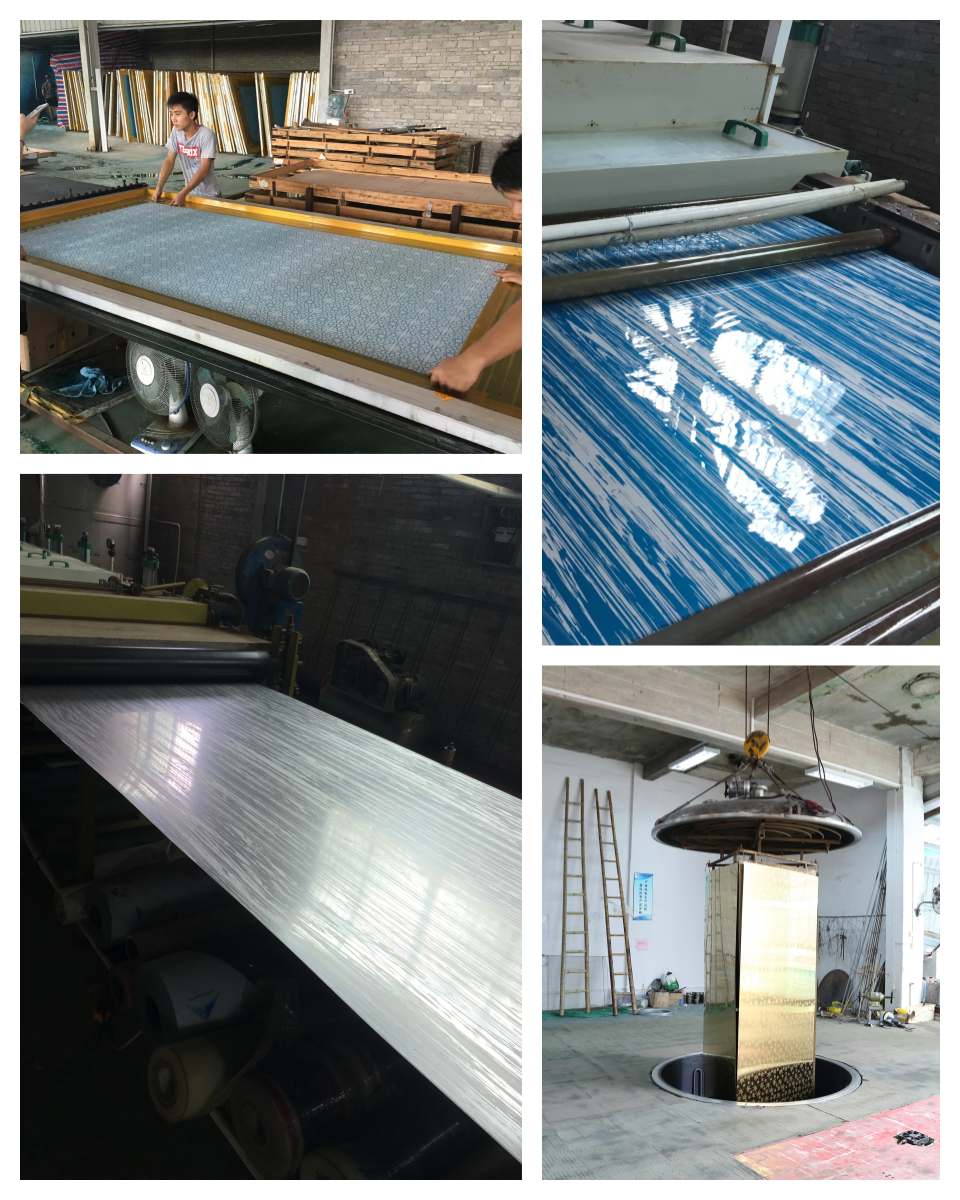

The stainless steel etching sheet for Elevator Door Sheet is chemically etched on the surface of stainless steel to produce various required patterns.The pre-prcess sheet can be 8K mirror finish,hairline finish and sandblasting finish.After etching,the etching sheet surface can be further processed.Stainless steel etched sheets can be used for complex processes such as partial processing,brush,color coating,and partial titanium plating.The stainless steel etched sheet is light and dark patterns and brilliant colors.

| Name | Deep Etching Stainless Steel for Elevator Door |

| Material Grade | Stainless Steel 201/304/316 |

| Thickness | 0.5-3.0mm |

| Size | 1000*2000mm 1219*2240mm,1219*2438mm,1500*3000mm |

| Color | Gold,Rose Gold,Bronze,Black,Champagne,White Gold,Brass,Etc |

| MOQ | 30pcs |

| Packing | PVC+ waterproof paper + strong sea-worthy wooden package |

| Payment Term | T/T, L/C at sight |

|

Chemical composition and mechanical properties of stainless steel coils |

|||||||||

|

Grade |

Chemical Composition (%) |

Mechanieal Performece |

|||||||

|

C |

Si |

Mn |

P |

S |

Ni |

Cr |

Mo |

Hardness |

|

|

201 |

≤0.15 |

≤1.00 |

5.5/7.5 |

≤0.060 |

≤0.030 |

3.5/5.5 |

16.0/18.0 |

- |

HB≤241,HRB≤100, HV≤240 |

|

304 |

≤0.08 |

≤1.00 |

≤2.00 |

≤0.045 |

≤0.03 |

8.0/11.0 |

18.00/20.00 |

- |

HB≤187,HRB≤90,HV≤200 |

|

316 |

≤0.08 |

≤1.00 |

≤2.00 |

≤0.045 |

≤0.03 |

10.00/14.00 |

16.0/18.0 |

2.00/3.00 |

HB≤187, HRB≤90 HV≤200 |

|

316L |

≤0.03 |

≤1.00 |

≤2.00 |

≤0.045 |

≤0.03 |

10.00/14.00 |

16.0/18.0 |

2.00/3.00 |

HB≤187, HRB≤90 HV≤200 |

|

410 |

≤0.15 |

≤1.00 |

≤1.25 |

≤0.060 |

≤0.030 |

≤0.060 |

11.5/13.5 |

- |

HB≤183, HRB≤88 HV≤200 |

|

430 |

≤0.12 |

≤1.00 |

≤1.25 |

≤0.040 |

≤0.03 |

- |

16.00/18.00 |

- |

HB≤183, HRB≤88 HV≤200 |

The surface design of this Etching Stainless is specially used in the interior of the elevator cabin,using different surface processes,including mirror polishing,brushing,etching and color plating.The standard size of this product is 1219mm*2438mm,or 1219*2240mm,or can be customized size. We strive to meet the needs of every customer.Stainless steel elevator cabin sheets can be provided,but also Stainless steel elevator door sheets with matching patterns can be provided.

Stainless Steel Etching Solution

Stainless steel has good characteristics such as unique strength and superior anti-corrosion performance,making its application prospects more and more extensive,but the application and development of stainless steel largely determines the development of its surface treatment technology.Stainless steel surface treatment technologies mainly include the following:

Stainless steel electroplating:due to the passivation state of the stainless steel surface in the air,it must go through a special pre-treatment process before electroplating before normal electroplating.

Passivation of stainless steel:All stainless steel parts,such as electroless plating or other coating requirements,generally have to undergo passivation treatment before they can be used as finished products or assembled into components.

Polishing of stainless steel:In order to obtain the brilliance,brightness and prolong service life of the stainless steel surface,the stainless steel may be mechanically polished,followed by chemical or electrolytic polishing.

Stainless steel coloring:Different colors can be obtained on the surface of stainless steel by means of chemical and electrolytic coloring,such as black,colored and so on.

Application

Because stainless steel has a metallic texture and different colors,it has a good decorative effect on the elevator and is the most commonly used material for elevator cabin and elevator doors.

FOSHAN TYSING METAL PRODUCT CO.,LTD is focus on stainless steel surface process and other stainless steel products for more than 16 years.

Our core team has more than 10 years experience on this period, adhering to the high standard quality requirements and competitive market prices.Our products are widely sold at local market and abroad. In recent years, based on long-term cooperation system.

FAQ:

1. How to get quotation?

Confirm the stainless steel grade 201/304/316/43.

The stainless steel sheet size,standard size is 1219*2438mm

The thickness 03-3.0mm

The quantity

The surface finish and color.

Better let us know what is the usage.

Then we can know quote best price for you.

2. What is the Minimal Order Quantity(MOQ)?

Usually our MOQ is 50pcs.If have special request,we can check the quantity together.

3. Can you OEM or ODM?

Yes we can.We can make stainless steel sheet following you sample.And make right package for you.

4. What is your lead time?

7 Days for sample.

25-30 Days for bulk production.

Tags :