Sign up to get the latest product announcement and offer.

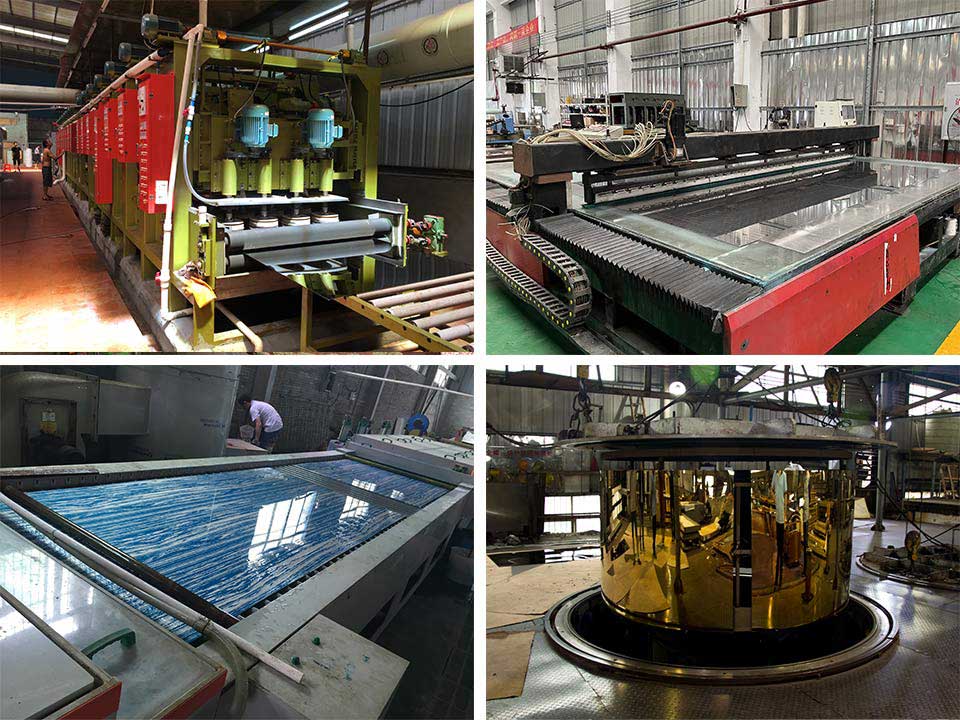

We made customized mold to make this shape of pattern.It is done by placing the Stainless Steel Sheet 0.7mm Sheet metal between a die and punch and then applying pressure to the metal to form it into the desired shape. The process can be used to create complex shapes with tight tolerances.

Grade: :

201 304 316Surface: :

Middle Water Ripple FinishSize: :

1219*2438mm,1219*3048mm or customizedColor :

Silver,Gold,Rose Gold,ChampagneLead Time: :

7-25 days after depositPackage: :

Wooden box+waterproof paper+Protect filmPayment Terms :

L/C at sight,T/T 30% deposit,70% balance before shipment.MOQ :

30pcsHammered Stainless Steel Sheet Metal Stamping 0.7mm

FOSHAN TYSING METAL PRODUCT CO.,LTD focuses on stainless steel surface process and customized products for more than 16 years.

Our core team has more than 10 years experience on this period, adhering to the high standard quality requirements and competitive market prices.Our products are widely sold at local market and abroad. In recent years, based on long-term cooperation system.

|

Product Name |

Hammered Stainless Steel Sheet Metal Stamping 0.7mm |

|

Thickness |

0.30mm-3.00mm or as required |

|

Size |

1000*2000mm 1219*2438mm 1219*3048mm 1500*3000mm or be customized. |

|

Standard |

AISI, JIS, GB, etc |

|

Surface Finishing |

Big water ripple finish |

|

Material |

201/304/316/430/etc |

|

Application |

Elevator interior/Architectural/Cladding/Interior decorations |

|

MOQ |

30 sheets |

|

Lead Time |

Within 15~30 days after receiving deposit |

|

Packing |

Standard Export Seaworthy Wooden Package/or as required |

|

Capacity |

50,000 PCS Production Capability/Month |

Stainless Steel Metal Stamping surfaces can be made on 2B, mirror, and brushed finish surface. PVD color coating can be made before stamping,still be in good surface after stamping.

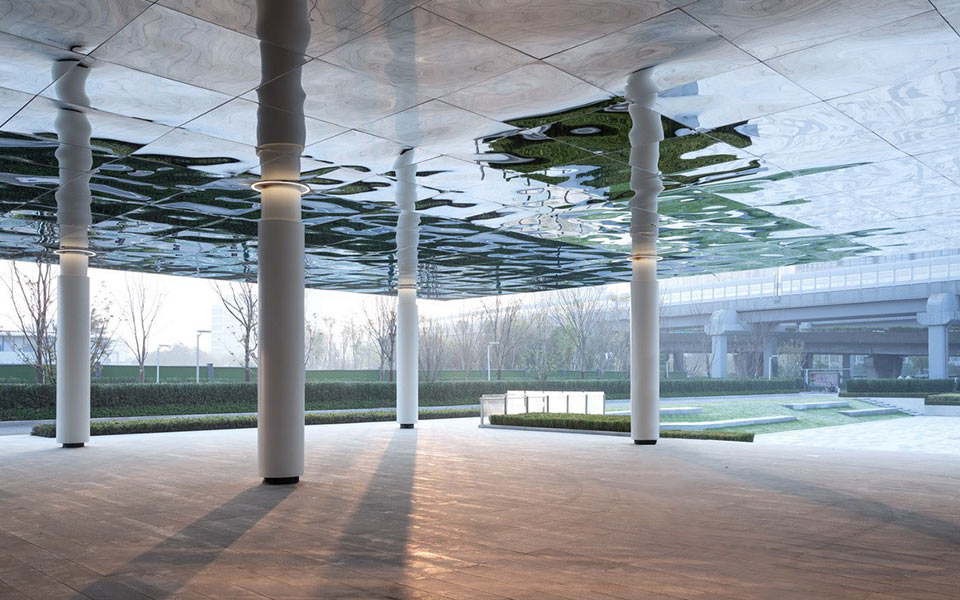

APPLICATION

Punched Stainless Steel Sheet has a strong decorative and fashion effect, so it is widely used in ceiling and wall decoration of hotels and shopping malls. And it is easy to clean, maintenance-free, anti-fingerprint, etc. If there is any stain, just wipe it with a cloth.

304 and 201 stainless steel are the most widely used materials for decorative corrugated panels. To save cost, 201 can be used in places where the air is dry. If the climate is humid and rainy, we recommend using 304 grade stainless steel.

what is the advantage of stamping stainless steel sheet

Stainless steel sheet stamping offers a number of advantages,including:

1. Durability: Hammered Stainless Steel Sheet is highly resistant to corrosion and abrasion,making it an ideal material for stamping parts that will be exposed to harsh environments.

2. Strength: Stainless steel is much stronger than other metals,allowing for thinner sheets to be used in the stamping process.This can result in lighter parts with greater strength.

3. Cost-effectiveness: Stainless steel is relatively inexpensive compared to other metals,making it a cost-effective choice for many applications in Stainless Steel Sheet 0.7mm.

4. Versatility:Stainless steel can be stamped into a variety of shapes and sizes,making it suitable for a wide range of applications.

We gradually created a complete supply system based on stainless steel, Stainless steel copper and other metal materials surface deep processing. Provide customers with one-stop solutions for metal products.

Stainless steel plate packaging and transportation

1.The stainless steel sheet is covered with waterproof paper for protection during transportation.

2. All stainless steel sheet will be packed in strong wooden boxes or wooden frames.

3.Professional loading workers,the package will not get hurt in delivery.

4. Take pictures in the container and seal the box.

5. Mature freight forwarding company provides fast and favorable shipping

Tags :